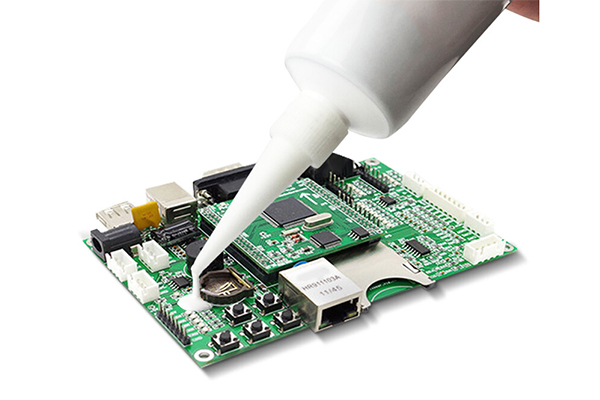

Electronic circuit board potting adhesive is a kind of adhesive suitable for industrial field. It can seal and bond electronic components of various sizes and shapes with good effect. In recent years, this type of adhesive has a good development and is widely used in the industrial field. With the expansion of the scope of use, the quality and performance are improved.

What should be paid attention to when using PCB Assembling circuit board potting glue?

1. It is very important to mix the AB glue according to a fixed proportion. Before mixing, carefully observe to see if the two groups of materials sink. Sometimes it will sink after being stored for a long time. It should not affect the normal use. Shake it evenly.

2. If the components need to be covered with the glass cover, please note that it must wait until the electronic circuit board potting compound is completely cured before plugging. Blocking before curing will seriously affect the curing effect.

3. The potting adhesive for PCB Components Assembly is not corrosive and will not corrode any material, which can be assured. Cooperate with powerful brand suppliers and be more confident. For example, Cosmore focuses on the research of electronic circuit board potting adhesive and provides customized electronic circuit board potting adhesive application solutions. It has a wide range of applications and can be used in new energy, military, medical, aviation, shipbuilding, electronics, automobile, instrument, power supply, high-speed rail and other industries.

Is the process of potting sealant for electronic circuit board complex? At present, there are various methods for glue filling. According to the way materials enter the mold, there are two ways: pouring and pressure injection. Pouring is to allow materials to enter the mold automatically. Pressure injection requires external pressure. External force helps in the process of material pouring and curing. Among them, the pouring can be divided into vacuum pouring and common pouring. If the requirements for curing effect are high, vacuum pouring is recommended.

Post time: Dec-08-2022